We refurbish and service high-voltage synchronous and asynchronous electrical machines

voltage level up to 10 kV.

High voltage service program includes:

* Degreasing, washing and drying of all parts of machines

* Refreshing the coil insulation

* Dynamic balancing of rotating masses

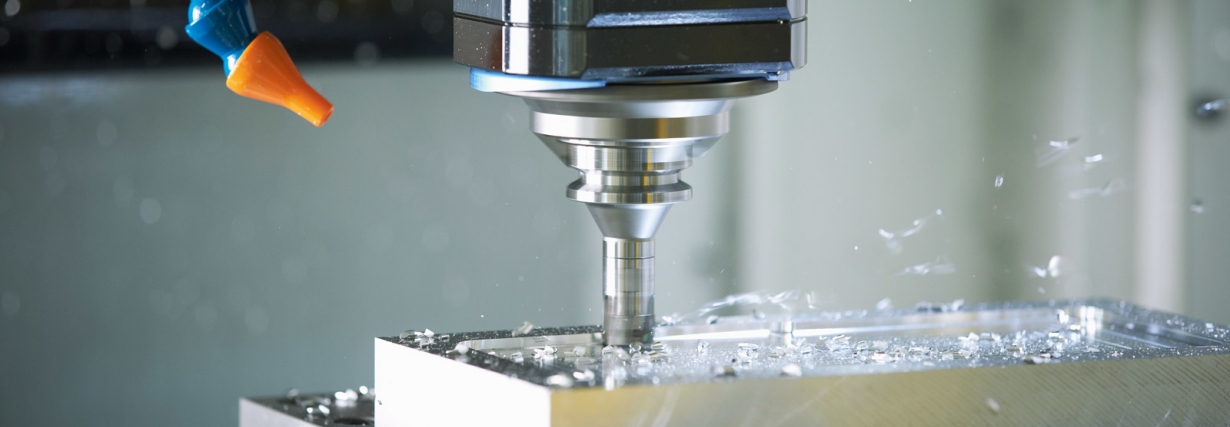

* Repair, construction and replacement of damaged parts

* Idle testing and development of test protocol

The program overhaul of HV machines includes:

* Preparation and replacement of stator and rotor coils in the "F" class insulation.

* Repair and development of the rotor cage

* Pre-packing tin metal packets for the stator and rotor

* Dynamic balancing of rotating masses

* Mechanical systems control

* Determining bearing validity with the SPM method

* Replace damaged parts with original parts or fabrication of new (shafts, bearing shields, fans, secretory case, terminal boards, sliding rings, etc.)

* Impregnation of the coils with high quality paint vacuuming process.